GM Technology

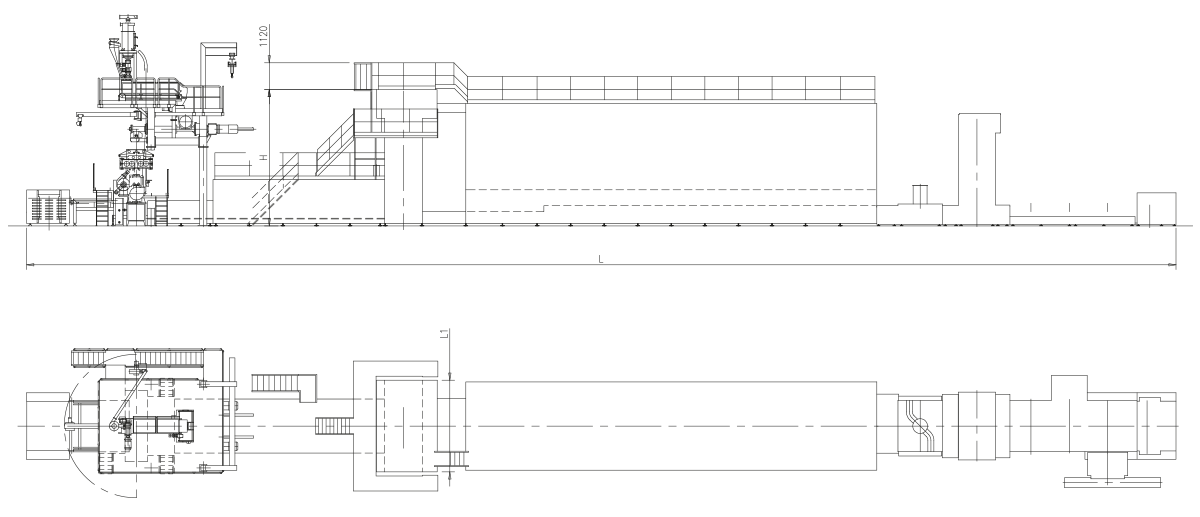

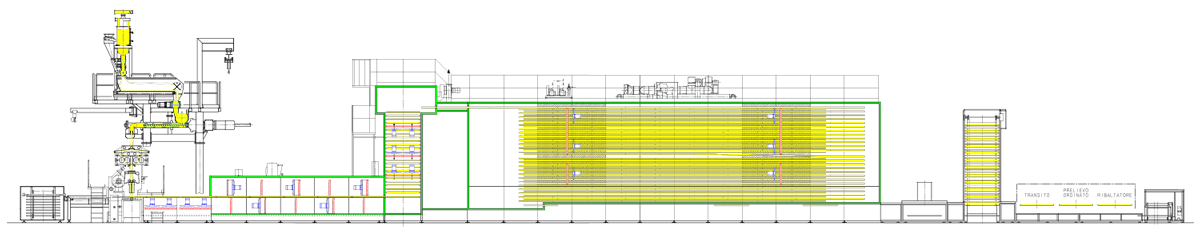

GM Functional diagram

The GM tray drying line is extremely versatile and responds perfectly to the drying requirements of specialty shapes such as nests, lasagna, cannelloni and jumbo shells. The constructive and technological characteristics of this line allow to obtain ideal drying diagrams for each and every raw material used.

It is combined with a press, which has a dough mixing system that can be one of the following: Total Vacuum, Stabilization Belt or Traditional Mixer, or a dough-sheeter for producing laminated pasta. The forming head section is dimensioned based on the specialty product required.

The pasta is placed on trays of various sizes depending on the production capacity of the line. The original shape of the pasta extruded in the forming phase is maintained throughout the process. An important innovation was made in the initial predrying phase where the pasta is exposed to high temperature treatment with a highly efficient ventilation system.

After the traditional vertical column predrying phase, an improved mechanical design and upgraded ventilation system optimized over time, the trays enter the multi-tier dryer, longitudinally developed, that provides a particularly extensive surface area.

No other dryer of similar dimensions can provide as much useful surface area on which even extremely lightweight pasta shapes can be processed.

The uniformity of the heat treatment is ensured by the fact that all trays transit through the same ventilation points.

The final part of the drying cycle is dedicated to stabilization. At the outlet of the dryer, the product is cooled in high performing cooling modules equipped with cold water coils.

In order to satisfy current packaging necessities, the line features two combined tray storage systems, which store full and empty trays alternately, to cope with possible operational downtimes in the packaging machines.

The above solution renders the packaging lines independent from the production cycle, thus optimizing the packaging phase.

Full trays can be emptied in bulk or can be packaged; in the latter case, the tray is automatically conveyed to the relevant packaging system.

The innovative electronic supervision system is intuitive and easy to use and ensures that you can run the line and all production cycle phases in a flexible and reliable manner. It integrates perfectly with the pasta factory control system to guarantee the exchange of all process data necessary for production control and product traceability.